When I initially made all the modifications to the wiring and added gauges, sensors, etc., I left the wires long on purpose. I wasn’t sure if I was going to have to reroute or modify anything after running her a bit. So, I basically coiled and zip tied as much as I could and stuffed everything under the tank and seat. This cycle of mods was all about cleaning up the rats nest under the tank and seat. Additionally, I needed to do something with the rectifier. I had two options, either relocate it under the bike as others have done, or make it fit under the tank. I went with the latter of the two. I wasn’t concerned with any heat issues because all last summer I had it jammed under the seat without any problems. It will get plenty of fresh air in its new home. I already had a good Dyna coil relocation place that I had purchased from a forum member, so I decided to modify that to make it work. Not the prettiest, but I think it’ll work. I also made better use of the additional space I had as a result of getting a Shorai lithium ion battery. Finally, I got a bar mount for my Dynojet pod300. That way I’ll be able to monitor everything and it’s much better than having it Velcro’d to the gas cap.

M

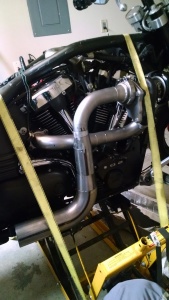

This what the plate looked like before I put the Dyna coils on the outside and did the turbo install.

This what the plate looked like before I put the Dyna coils on the outside and did the turbo install.